5*5mm External Wall Insulation Fiberglass Mesh Coated With An Emulsion

Introduction

Fiberglass mesh is woven by fiberglass yarns, then alkaline-resistant latex coated. It owns great alkaline-resistant and high strength. As a perfect engineering material in construction, It is widely used to reinforce cement, stone, wall materials, roofing, gypsum and so on.

Fiberglass mesh on the basis of C-glass or E-glass fiberglass woven mesh, then coated with alkali resistant liquid. It possesses properties of high strength, good cohesion, and anti alkali. Fiberglass mesh is woven by fiberglass yarn as its basis mesh, and then coated by alkaline resistant latex. It has fine alkaline-resistant, high strength, etc. As an ideal engineering material in construction, it is mainly used to reinforce cement, stone, wall materials, roofing, and gypsum and so on.

Specification

Material of the base:Fiberglass yarn

Type of weave (name):Leno

Hole Size:2.8x2.8mm,4x4mm,5x5mm,10x10mm

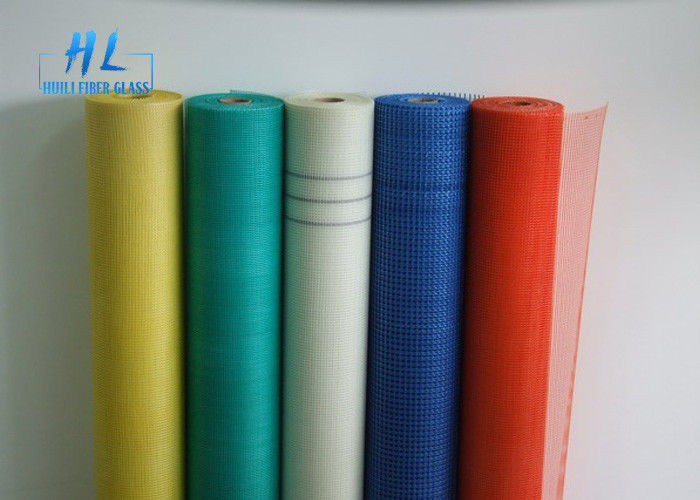

Colored fibers woven:White,Green,Blue,Orange,and any color

Coating:Latex Coating, Urea Coating

Length of the roll:30m,50m,100m.

Height of the roll:0.2m,0.5m,1m,1.2m,1.5m,1.8m,

Weighting:45g,80g,100g,110g,120g,150g,160g and so on.

| NO. |

Specifications |

Mesh size

mm |

Yarn density

(tex) |

Mass

g/m2 |

Tensile strength

N/5X20cm |

| warp |

weft |

warp |

weft |

warp |

weft |

| 1 |

4×4-75 |

4 |

4 |

48/2 |

200 |

75±3 |

700 |

850 |

| 2 |

4×4-90 |

4 |

4 |

67/2 |

200 |

90±3 |

950 |

1100 |

| 3 |

4×4-145 |

4 |

4 |

134/2 |

240 |

145±5 |

1500 |

1500 |

| 4 |

4×4-160 |

4 |

4 |

134/2 |

300 |

160±5 |

1500 |

1650 |

| 5 |

4×5-110 |

4 |

5 |

100/2 |

360 |

110±5 |

1100 |

1200 |

| 6 |

4×5-125 |

4 |

5 |

100/2 |

280 |

125±5 |

1200 |

1300 |

| 7 |

4×5-145 |

4 |

5 |

134/2 |

300 |

145±5 |

1400 |

1400 |

| 8 |

4×5-160 |

4 |

5 |

134/2 |

360 |

160±5 |

1500 |

1600 |

| 9 |

5×5-90 |

5 |

5 |

67/2 |

240 |

90±3 |

950 |

1150 |

Usage

1. 75g / m2 or less: Used in the reinforcement of thin slurry, to eliminate small cracks and scattered throughout the surface pressure.

2. 110g / m2 or about: Widely used in indoor and outdoor walls, prevent the various materials (such as brick, light wood, prefabricated structure) of treatment or caused by a variety of expansion coefficient of wall crack and break .

3. 145g/m2 or about: Used in the wall and be mixed in various materials (such as brick, light wood, prefabricated structures), to prevent cracking and scatter the whole surface pressure, especially in the external wall insulation system (EIFS ).

4. 160g / m2 or about: Used in insulator layer of reinforcement in the mortar, through shrinkage and temperature changes by providing a space to maintain movement between the layers, prevent crack and rupture due to shrinkage or temperature.

Feature

1.Excellent alkaline resistance and corrosion resistance

2.High tensile strength and impact resistance

3.Good dimensional stability and deformation resistance

4.Good adhesion with resins and water resistance

5.Temperature stability and flame resistance

6.Soft, flexible and well arranged, simple and easy to apply

7.Resistance to aging

8.Durable, versatile and cost-effective

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!